In the wake of global health crises, the demand for face masks has reached unprecedented levels. To meet this demand efficiently and sustainably, the manufacturing industry has embraced advanced technologies. Among these, Flat Mask Making Machines have emerged as crucial tools in the production of high-quality, reliable face masks.

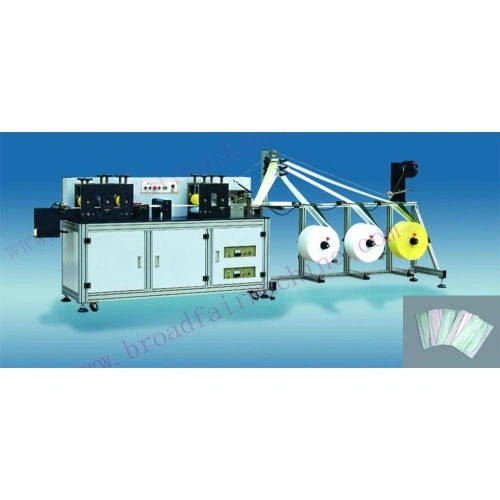

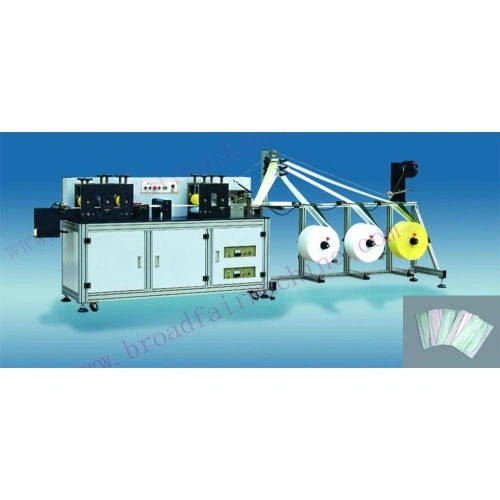

The Rise of Flat Mask Making Machines Flat Mask Making Machines represent a paradigm shift in mask production. Unlike traditional methods that heavily rely on manual labor, these machines are automated, allowing for the rapid and consistent manufacturing of masks. Their emergence has been pivotal, especially during pandemics, where the need for masks surged globally. How Flat Mask Making Machines Work Flat Mask Making Machines operate through a series of automated steps: Material Feeding: The machine takes in raw materials, typically layers of non-woven fabric, melt-blown fabric, and nose bridges, from rolls or stacks. Folding and Cutting: The materials go through folding and cutting processes, shaping them into the desired mask size. Ultrasonic Welding: Ultrasonic technology is employed to weld the different layers together, ensuring a secure and durable bond without the need for adhesives or additional materials. Ear Loop Welding: Elastic bands for ear loops are welded onto the masks, providing a comfortable and secure fit. Quality Control: Finished masks undergo quality checks, ensuring they meet the required standards before packaging. Advantages of Flat Mask Making Machines High Efficiency: Flat Mask Making Machines can produce thousands of masks per hour, ensuring a swift response to market demands. Consistent Quality: Automation reduces the risk of human error, guaranteeing consistent quality and adherence to safety standards. Customization: These machines are versatile and can produce various types of flat masks, including surgical masks, N95 respirators, and disposable masks. Cost-Effectiveness: Despite the initial investment, the high production capacity and low operational costs make these machines economically viable in the long run. Sustainable Production: Flat Mask Making Machines minimize material wastage and contribute to eco-friendly practices by optimizing resource use. Flat Mask Making Machines have revolutionized the face mask manufacturing industry, enabling large-scale production without compromising on quality. As the world faces ongoing health challenges, these machines play a vital role in ensuring that high-quality masks are readily available to protect communities. Their efficiency, consistency, and adaptability not only meet market demands but also contribute significantly to global health and safety efforts. In the relentless pursuit of safeguarding public health, Flat Mask Making Machines stand as a testament to the power of innovation and automation in the face of adversity.

The Flat Mask Making Machines produced by our company mainly include Mask Blank Machines,Ear-loop Flat Mask Machines and Head-loop Flat Mask Machines.